Reliable self unloading systems that provide the highest-rated capacities

Gravity self-unloading systems

A bulk carrier equipped with a MacGregor self-unloading gravity system offers fast, reliable and efficient deliveries of free-flowing dry bulk commodities. Designed for both new buildings and converted vessels, each system is tailor-made to suit your vessel for maximum performance and efficiency. This system also has the ability to discharge onshore or offshore with either no, or minimal, capital investment at the receiving facility, and can be operative 24 hours a day, seven days a week.

MacGregor self-unloading gravity systems have benefited from decades of development and service experience since the first delivery of a self-unloading ore carrier in 1956.

Key benefits:

- Advanced and well-proven technology

- Very high unloading rates

- Designed for newbuildings as well as conversions

- Tailored to suit each vessel for maximum performance and efficiency

- Environmentally-friendly operation

- Low energy consumption

- Low maintenance costs

GravityVibeTM

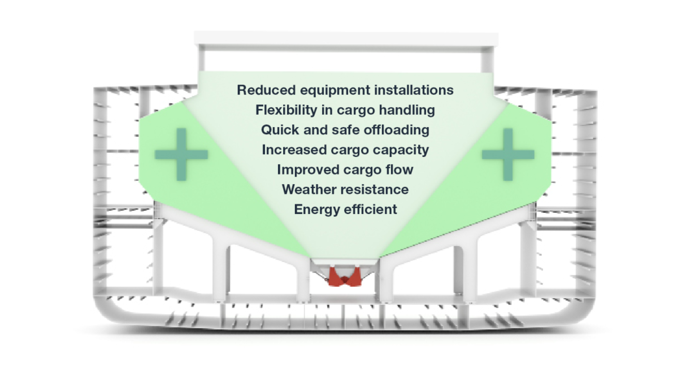

MacGregor has further developed the Gravity systems and has developed a new system, MacGregor GravityVibeTM. In addition to the key benefits of the standard Gravity systems, the MacGregor GravityVibeTM will give the following key benefits:

- A system that offers improved Cargo flow

- Extended flexibility, will handle a wider range of material

- A cost-efficient system, as fewer subsystems are needed

- The system will in most cases give more volume in the holds

- Increased sustainability viewed from a Life cycle perspective

The new design will allow the cargo flow to be lined up on a single line with only one hold conveyor at the bottom of the holds. That will give a simplified unloading sequence and limit the transition points compared to the standard system. At the same time, some of the subsystems ( hold conveyors, cross conveyors) will be removed, giving a cost-efficient system.

Cement handling systems

Since the 1960, MacGregor cement handling systems have been installed on over 140 on cement carriers sized between 500 and 40,000 dwt; most of these are still in operation.

Applications

Our cement handling system comprises a range of distribution arrangements, both mechanical and pneumatic, which can be combined to deliver the required function and cargo handling rates. Easily adaptable to any size and shape of vessel, the system is suitable for newbuildings as well as conversions. Overall, the system ensures the reliable and highly-efficient seaborne transportation of cement from producers to consumers all over the world. It is designed for use with range of different receiving systems and is therefore able to load and unload in many different terminals.

Dust-free material handling

The shipboard solutions for cement carriers are designed with unique screw conveyor technology, which incorporates a totally-enclosed conveying line for environmentally-friendly operation in all weather conditions.

Our screw conveyors are used both for mechanical loading and unloading of cement carriers and for the transfer of cargo between ships and shore based facilities. Screw conveyors are designed to handle powdery cargoes such as cement, fly ash and limestone powder under tough conditions. They are completely enclosed for dust-free operation.

All our pneumatic systems also offer dust-free operations.

MacGregor GravityVibe webinar recording

See the recorded webinar from February 2024 about the MacGregor GravityVibeTM - a new gravity self-unloading system that enhances flexibility and efficiency in bulk handling.