Can container optimisation offer a boost to decarbonisation?

14 Oct 2024 Reading time calculated textNaval Architect

October 2024

Deck & cargo equipment

p.16-17

Link to original article

image text: MacGregor's ISO Gap Adapters make it possible for ‘Russian stow’ of 40ft containers over hatch covers

Enhanced stowage solutions from MacGregor are allowing container ship operators to maximise cargo intake and reduce environmental footprint.

Much of the discussion concerning maritime decarbonisation focuses around solutions that will be familiar to readers of The Naval Architect: hull form optimisation, speed reduction and engine de-rating, the adoption of new fuels and energy storage, and emerging technologies such as wind propulsion and carbon capture and storage.

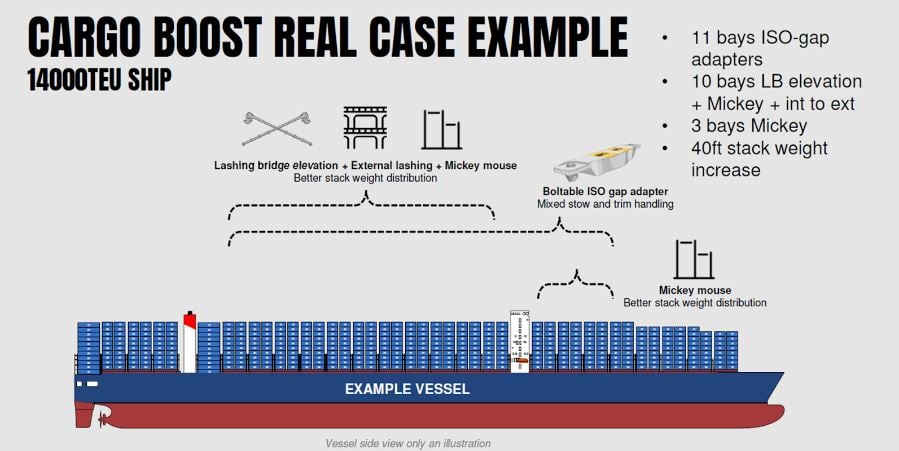

But a somewhat neglected component is maximising a vessel’s cargo-carrying potential; something that’s particularly true of many container ships, according to cargo handling specialists at MacGregor. The company calculates that its own Cargo Boost solution could reduce the environmental footprint of container shipping by more than 10%. This can be achieved for an individual ship whose cargo system will be upgraded, but as an example it can be also thought that this could be done through cutting the number of vessels required for transportation. In simple terms – contingent upon size and operating profiles – where currently 11 vessels are used with optimal utilisation it might be possible to use only 10.

“Nobody is really focusing on improving the cargo system, although all the top 10 liner operators understand its importance. We are working on several projects with leading global shipping companies like Hapag Lloyd, but in the broader industry it’s not as widely recognised,” says Arto Toivonen, MacGregor’s sales manager for Lashings and Cargo Boost.

When it comes to container shipping, cargo optimisation is a specialised discipline that may not always receive the same level of focus at shipyards, where the primary emphasis is often placed on key elements such as hull design, main engines, and the deckhouse. Even while container ship sizes and capacities grew exponentially over the last 15-20 years, many yards continued to make lashing bridges too low and with low stack rate hatch covers.

Toivonen explains: “They didn’t always appreciate that as the ship grows bigger the cargo system has to perform better. Because the vessel is wider you can load much more stability wise. Suddenly, the lashing system started to become a bottleneck. If you have a 16,000TEU vessel and have only two-tier-high lashing bridges instead of three- or four-tier-high then you can’t put heavy containers on deck, everything is in the hold. This makes GM high and the cargo carrying capacity inefficient.”

To complicate matters further it’s not uncommon for the lashing bridges, lashing systems and other equipment used to hold the cargo in place to come from multiple suppliers, creating problems with compatibility. Small wonder then that many container ships only operate to around 80% of their theoretical capacity.

image text: Earlier this year MacGregor completed cargo system upgrades for two Thalassa series ships, Norfolk Express and Savannah Express, operated by Hapag-Lloyd. The project included elevation of lashing bridges, addition of ‘Mickey Mouses’ and increased flexibility for mixed stow of 20/40ft containers on deck

Cargo Boost

MacGregor is regularly consulted in newbuilding projects and works closely with many shipyards and shipowners in developing optimal stowage solutions, but there is also a burgeoning market in aftersales and retrofits. First launched around a decade ago, MacGregor Cargo Boost is a service designed to maximise cargo space utilisation and help the competitiveness of those older vessels in particular, bringing them closer to their theoretical capacity.

At the simplest level significant improvements can be achieved by what MacGregor describes as a ‘paper exercise’, scrutinising the vessel’s Cargo Securing Manual to determine where gains can be made by updating to the latest class rules, which are often more sympathetic to increased payloads. Also maximum container stack weights can be increased by the paper exercise only, which further boosts the benefits gained from the latest class rules. MacGregor says that hundreds of vessels have benefitted from this service alone without any physical alterations to the vessel.

But even greater benefits can be realised with retrofitting of enhancements such as elevating existing lashing bridges or so-called ‘Mickey Mouses’ – towers on the wind-exposed outermost rows of lashing bridges – which make it possible to add additional tiers of containers while also building a windshield for the innermost rows of containers. These can be built on top of existing lashing bridges with some additional strengthening such adaptations also usually include a switch from internal to external lashing systems, which allow for a greater payload and lower the ship’s GM.

Another commonly employed solution under Cargo Boost is the employment of ISO Gap Adapters; boltable fittings that can be installed on existing container sockets with 20ft lashing gaps in the middle of hatch covers. The advantage of this is that it enables what is known as ‘Russian-stow’ i.e. mixed stow – whereby 40ft containers can be loaded on top of two 20ft containers – which wouldn’t otherwise be possible for older wide-beamed vessels.

“Without this you have to load heavy twenties at the bottom of the cargo hold and if the vessel is very wide it’s usually too stiff, making accelerations less favourable. But if the heavy twenties can be stored on deck these movements can be much smoother, which means you can load more because the GM is lower,” says Toivonen.

A vessel that has been cargo optimised also has benefits for fuel consumption as there should be less instances when ballasting is required, since cargo can be loaded more flexibly, therefore reducing the emissions per TEU. More cargo will be carried around with the same fuel consumption as before the cargo boost.

image text: Using Cargo Boost, MacGregor says it can increase a vessel’s utilisation rate from 80% to around 90-95%. Including steel and fabrication, such a project would cost around US$2.9 million for a 14,000TEU vessel.

While it’s theoretically possible to install a Cargo Boost solution within just a few weeks with adequate preparation they are more commonly carried out in parallel with other retrofitting projects such as scrubber installation. Toivonen says that from initial study, through to design and ultimately completion a more typical timeframe is around seven months and when incorporated into more extensive retrofitting like increasing the ship’s draft or even extending its length then cargo capacity increases in excess of the theoretical maximum have been achieved.

To assist shipowners in better understanding the savings potential of their solutions it has also developed a Carbon Calculator that can be accessed on its website and allows users to insert a range of parameters to determine the savings both as reductions in ETS (Emission Trading Systems) payments and as fuel costs.

This article was written by Richard Halfhide and republished with permission from The Naval Architect, October 2024 issue.