MacGregor decarbonisation journey

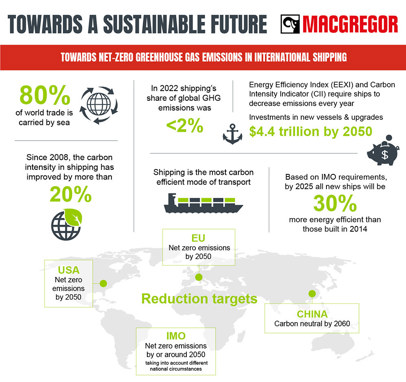

The maritime industry has started its journey towards a more sustainable future, driven by the IMO Strategy on Reduction of GHG Emissions for reaching net-zero greenhouse gas emissions from international shipping close to 2050 and external legislation like EU fit for 55, as well as stakeholders’ demands and initiatives.

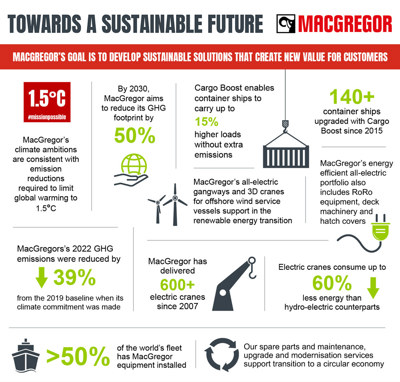

As the leading provider of maritime cargo and load handling solutions, MacGregor is committed to doing its share for the decarbonisation of the industry and to pursuing science-based measures to limit global temperature rise to 1.5°C. We aim to significantly reduce our own emissions, and help our value chain including customers to reduce emissions of their operations.

Helping customers solve their sustainability challenges

MacGregor is committed to offering products and services that help customers mitigate environmental risks, optimise cargo flows and port turn-around times, and reduce energy consumption and overall operational costs with a focus on safety and maximising equipment availability.

Here are some examples of solutions that help customers solve their sustainability challenges:

MacGregor cargo-stowage optimisation enhances cargo-carrying efficiency

A holistic and tailored approach to designing stowage solutions is helping owners increase their earning potential and minimise the environmental footprint of their ships. On example is MacGregor Cargo Boost for container ships that can increase cargo carrying capacity by up to 15%.

MacGregor GravityVibeTM enables bulk carriers to deliver greater volumes

The new augmented gravity self-unloading system will allow bulk carriers to deliver a wider variety of cargo, in greater volume. The system deploys a vibrating unloader to reduce internal friction and ease the discharge of coarse materials such as wood chips from the cargo hold.

Electric cranes offer many benefits

MacGregor has delivered more than 600 electric cranes since 2007, with electric motor and drive system technology evolving significantly during this time. These developments have enabled the winch design, motor efficiency and cooling system to be further improved. As a result, the next generation electric crane is 15% more efficient than the first generation and up to 50% more efficient compared to the traditional closed-loop hydraulic design.

Contributing to the energy transition

MacGregor has designed and built solutions for the oil & gas industry for many years. Our extensive experience in this demanding sector, transfer of proven technologies and the development of automated solutions are supporting the progression of wind energy with a continuing focus on safety, reliability and optimum performance. One of the key equipment for service vessels of the offshore wind turbines is the Horizon gangway.

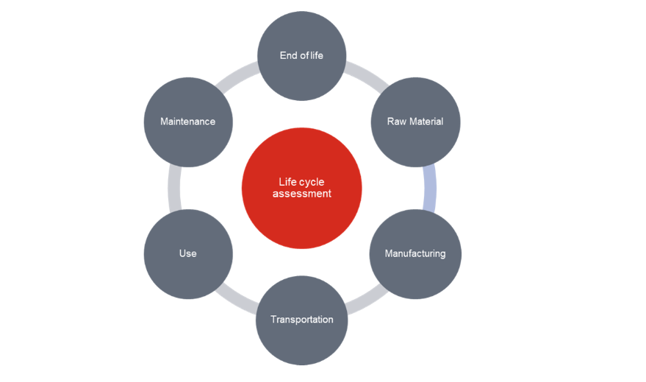

Driving Sustainability through Data - Carbon Footprint Declarations

MacGregor is adopting a data-driven approach assessing the environmental impact of its products throughout their lifecycle. The data collected from Life Cycle Assessments (LCAs) is summarized in Carbon Footprint Declarations (CFDs), offering a clear view of each product's carbon footprint. While LCAs and CFDs provide the critical insights needed for decision-making that drives carbon reduction.

Read more in the full article.

Share

Share